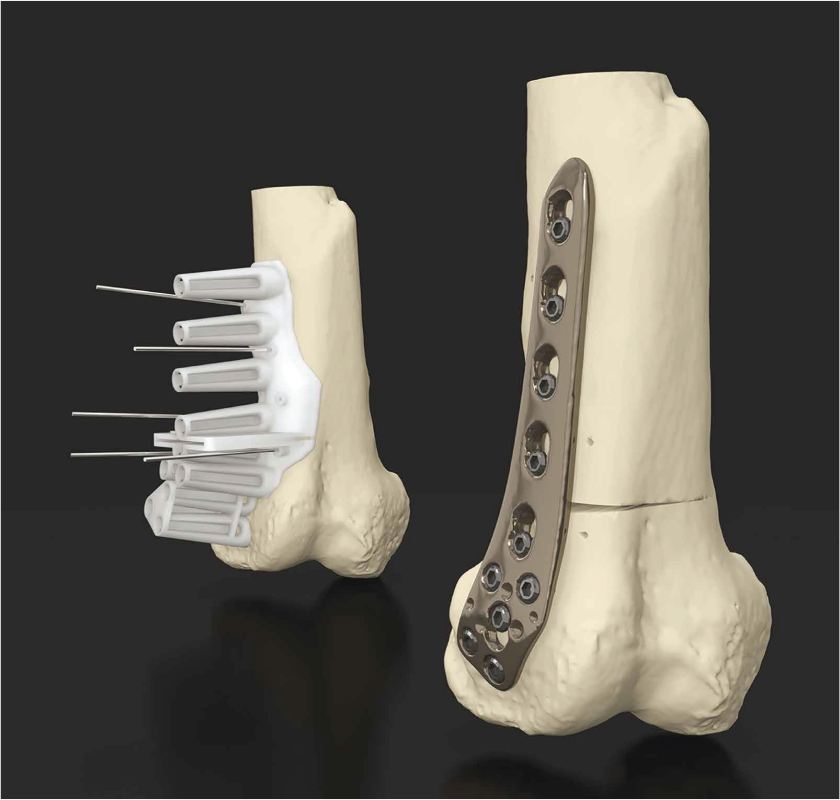

3D打印在骨科医疗器械制造中的应用

3D打印技术是一种快速成型技术,其主要通过计算机辅助设计软件的分层处理技术构建3D结构实体模型。3D打印在骨科医疗器械制造中发挥着重要作用,采用3D打印技术制作的骨科医疗器械种类较多,常见的有手术器械、

News information

3D打印技术是一种快速成型技术,其主要通过计算机辅助设计软件的分层处理技术构建3D结构实体模型。3D打印在骨科医疗器械制造中发挥着重要作用,采用3D打印技术制作的骨科医疗器械种类较多,常见的有手术器械、

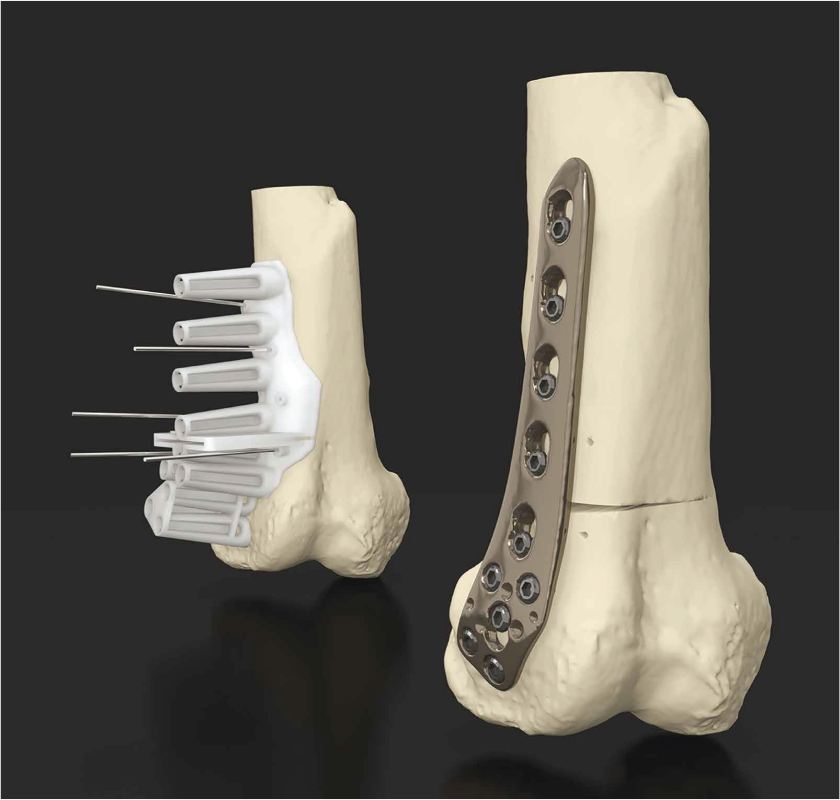

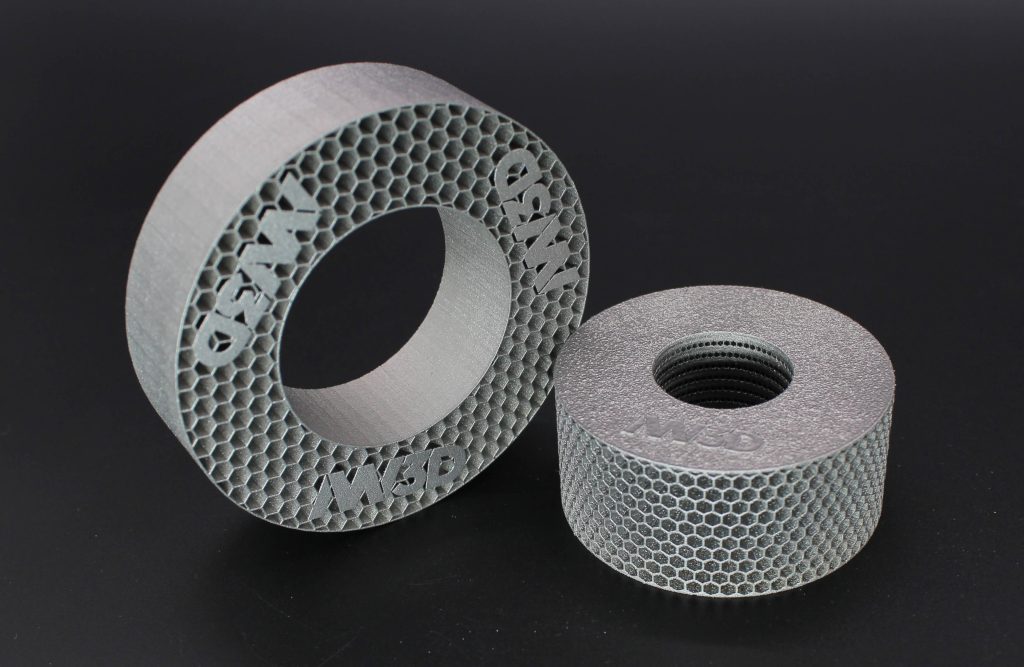

1.产品多样化:对于传统的生产制造方式,工件的形状越复杂,生产成本就越高。但对于3D打印技术而言,无论多么复杂的工件,都可以快速、准确地打印出来。 2.材料利用率高,降低成本:传统减材制造方法原材料的利

1.3D打印机又名:三维打印机、3D成型机、三维成型机、立体打印机、添加剂打印机等等,其在当今的工业应用中十分广泛, 大大缩短了建模、浇铸等工序, 提高了制作与生产的效率。 2.3D打印是添加剂制造技术

1. Scanning and forming can be performed by manipulating the magnetic deflection coil, without mechanical inertia. 2. The vacuum environment of the electron beam can also prevent the metal powder from being oxidized during liquid phase sintering or melting. 3. Laser deflection requires a galvanometer and a cooling system, and the focal length is difficult to change quickly. The electron beam deflection and focusing control is faster and more precise.

★ Laser printing retains the metal raw materials, no pollution, no impurities. ★ Uniform structure, retains the physical and chemical properties of the raw materials, no hidden dangers of cytotoxicity. ★ Good combination of gold and porcelain, not easy to collapse porcelain★ Especially for dental implant restorations with large amounts of gold, no deformation. ★ No high-temperature casting shrinkage, no need for segmented welding

Digital 3D laser printed cobalt-chromium steel tray ● Digital 3D laser printed steel tray 100% is pollution-free and impurity-free, retains the performance of raw materials, ensures high elasticity of the clasp and bracket, and improves the strength and toughness by 100-200% compared with traditional production, and fits perfectly with the oral cavity, is light and firm, and has a great foreign body sensation

1. Scanning and forming can be performed by manipulating the magnetic deflection coil, without mechanical inertia. 2. The vacuum environment of the electron beam can also prevent the metal powder from being oxidized during liquid phase sintering or melting. 3. Laser deflection requires a galvanometer and a cooling system, and the focal length is difficult to change quickly. The electron beam deflection and focusing control is faster and more precise.

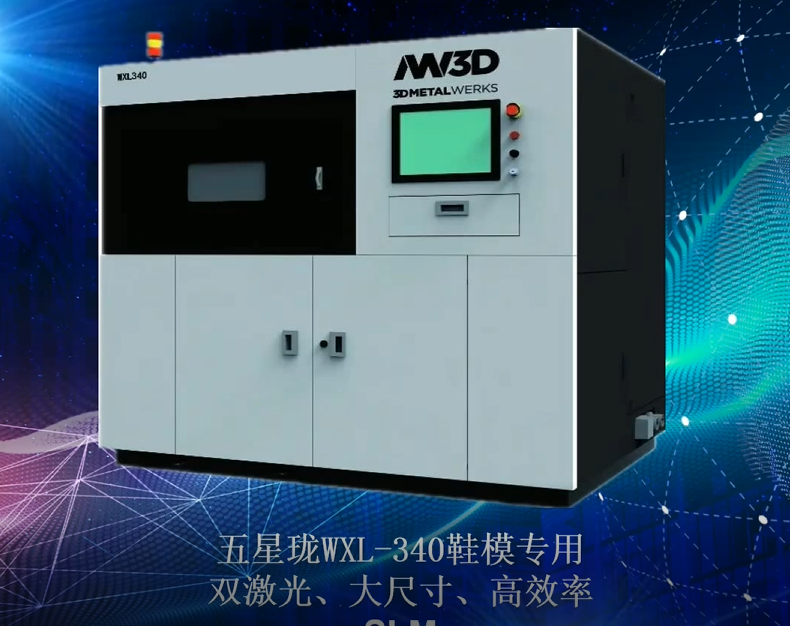

Time flies, and 2018 is coming to an end. 2018 is a year of opportunities and challenges for Wuxinglong Technology, but also a year of harvest. In 2018, with the care and support of leaders at all levels, Wuxinglong closely focused on the core concept of independent research and development of equipment, seized opportunities, sought

Copyright © 2024

Xiamen Wuxinglong Technology Co., Ltd.