S136H模具钢快进给轻量化带冷却流道可转位铣削刀体

与厦门金鹭特种合金有限公司合作,通过3D打印技术制造轻量化刀体,在高速进给时具有更好的动态性能,减少了振动和惯性力,进而提高了切削效率和加工精度。 在高速、高负荷的切削过程中,刀具的温度会迅速升高,导致

News information

与厦门金鹭特种合金有限公司合作,通过3D打印技术制造轻量化刀体,在高速进给时具有更好的动态性能,减少了振动和惯性力,进而提高了切削效率和加工精度。 在高速、高负荷的切削过程中,刀具的温度会迅速升高,导致

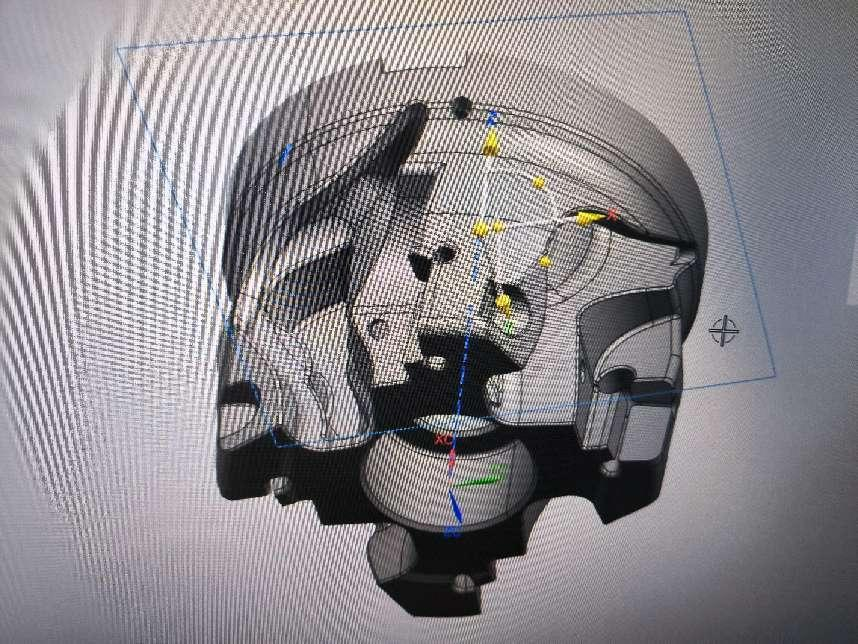

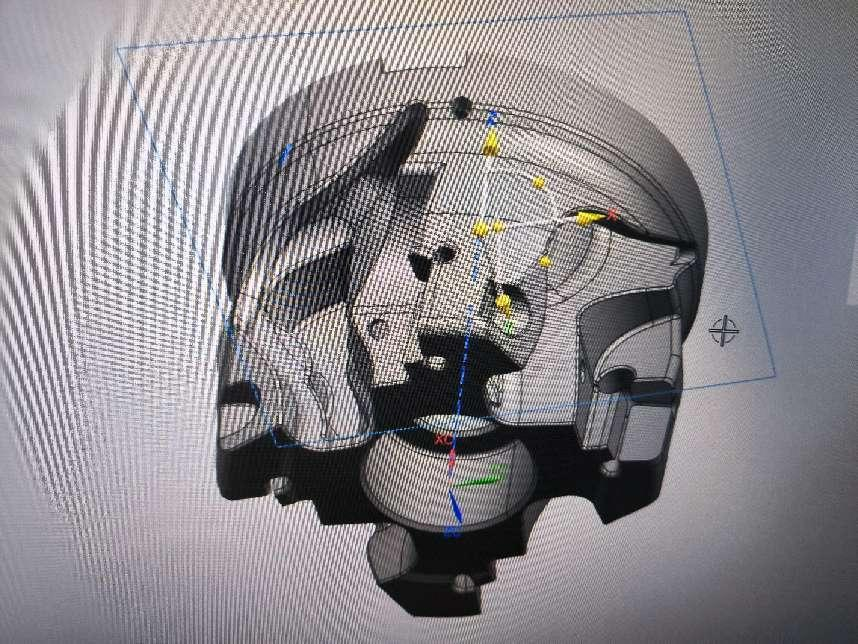

与美国Laser Photonics公司合作,开发一种使用3D金属打印技术打印的带随形冷却流道、为半自动和全自动激光产品定制设计的激光扫描头。

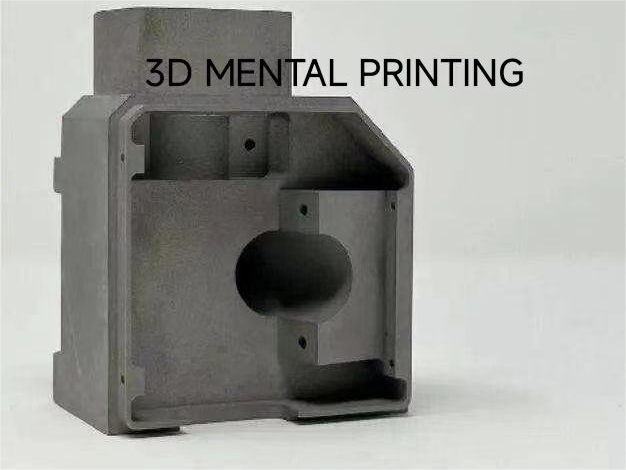

与建霖集团旗下卫浴模具公司合作,利用3D打印技术制造具有复杂几何形状和高精度的流道模具,根据卫浴产品的形状和尺寸进行定制化设计,实现流道模具的精确匹配,无需经过复杂的加工和装配过程,大大缩短模具的制造周

1. Adjustable parameters: Parameters can be adjusted according to the actual needs of customers to achieve the best printing effect. 2. Joint research and development: Jointly develop the application of various new materials with customers, and customize the best product full set of solutions. 3. High printing accuracy and good stability: Precision parts are imported products,

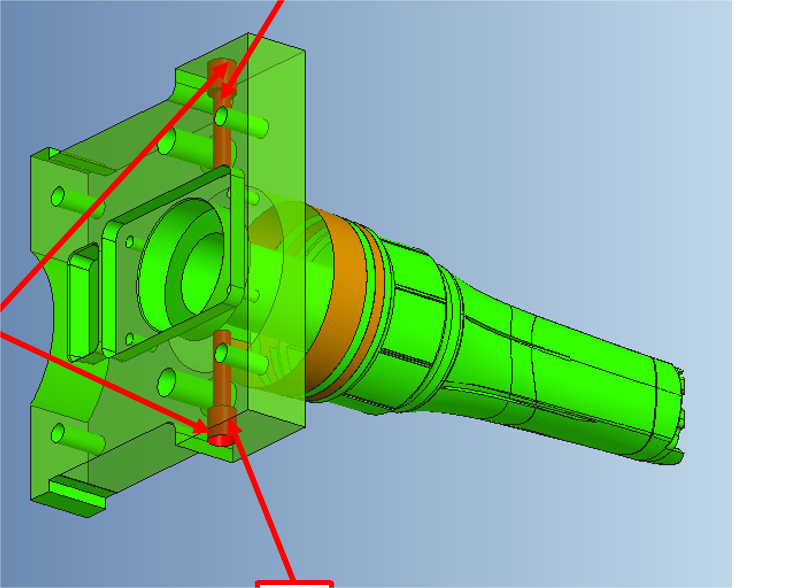

The process gas is introduced into the spray gun at a pressure of up to 50 bar and heated to a maximum of 1100°C. Subsequently, the process gas is accelerated to supersonic speeds and the gas is simultaneously cooled to a temperature below 100°C. The spray powder is injected into the converging part of the nozzle using a powder feed unit and a carrier gas and is then introduced into the main gas flow.

The process gas is introduced into the spray gun at a pressure of up to 50 bar and heated to a maximum of 1100°C. Subsequently, the process gas is accelerated to supersonic speeds and the gas is simultaneously cooled to a temperature below 100°C. The spray powder is injected into the converging part of the nozzle using a powder feed unit and a carrier gas and is then introduced into the main gas flow.

The process gas is introduced into the spray gun at a pressure of up to 50 bar and heated to a maximum of 1100°C. Subsequently, the process gas is accelerated to supersonic speeds and the gas is simultaneously cooled to a temperature below 100°C. The spray powder is injected into the converging part of the nozzle using a powder feed unit and a carrier gas and is then introduced into the main gas flow.

Copyright © 2024

Xiamen Wuxinglong Technology Co., Ltd.