MAKE FOR INNOVATION

MAKE FOR INNOVATION

Metal 3D printing total solution provider

METAL 3D PRINTING OVERRALL SOUTION PROVIDER

Wuxinglong closely follows the development trends of the industry, continuously strengthens the research and development of core technologies, always adheres to high-quality manufacturing, and strives to become a leader in the additive manufacturing industry and promote the digital transformation of the manufacturing industry.

Total area

Annual production capacity of various types of 3D printing equipment

Core technology patent

team member

Application Areas

Latest News

S136H模具钢快进给轻量化带冷却流道可转位铣削刀体

与厦门金鹭特种合金有限公司合作,通过3D打印技术制造轻量化刀体,在高速进给时具有更好的动态性能,减少了振动和惯性力,进而提高了切削效率和加工精度。 在高速、高负

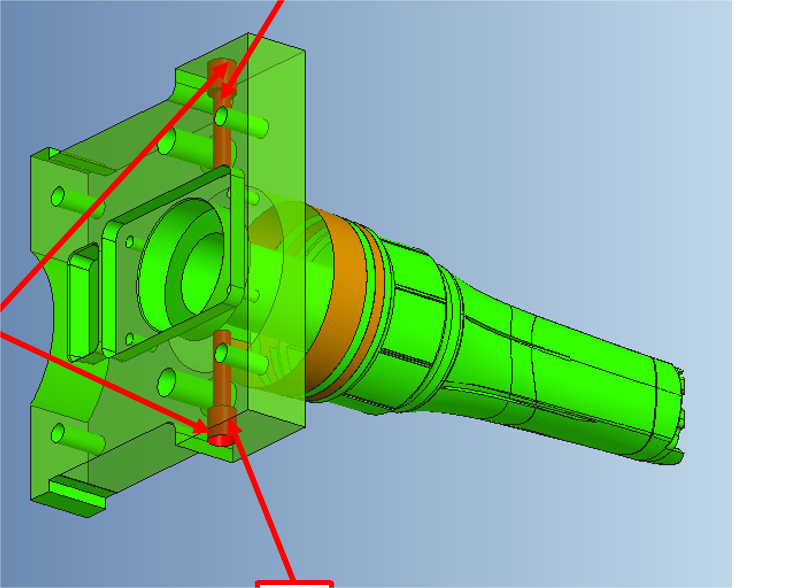

316L不锈钢3D打印带冷却流道的激光扫描头

与美国Laser Photonics公司合作,开发一种使用3D金属打印技术打印的带随形冷却流道、为半自动和全自动激光产品定制设计的激光扫描头。

3D打印花洒随型冷却流道模具

与建霖集团旗下卫浴模具公司合作,利用3D打印技术制造具有复杂几何形状和高精度的流道模具,根据卫浴产品的形状和尺寸进行定制化设计,实现流道模具的精确匹配,无需经过

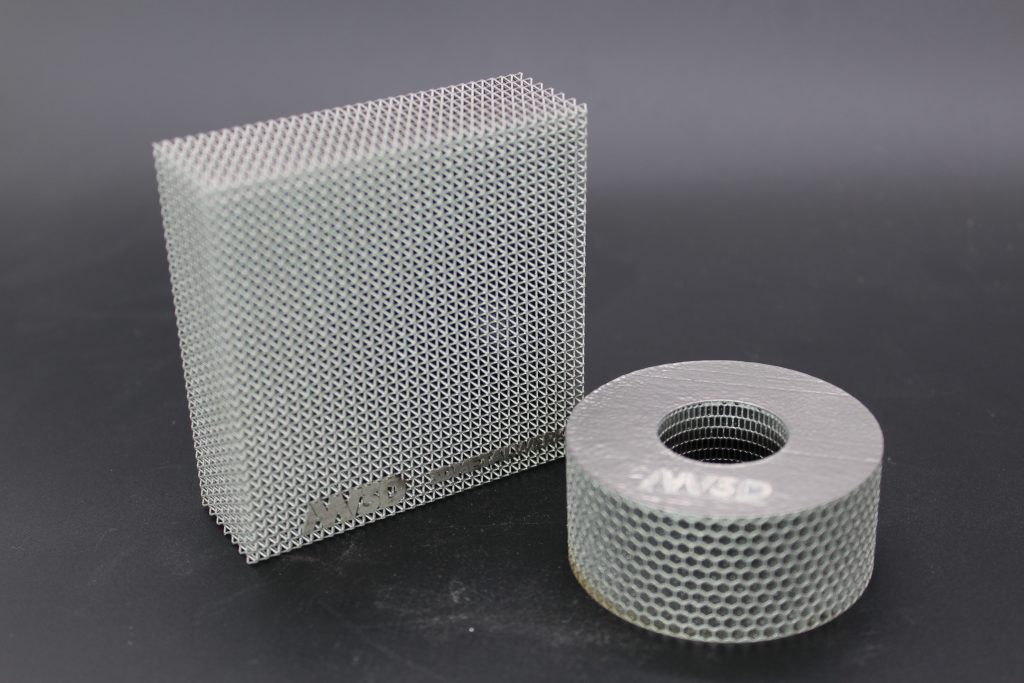

3DMETAL WERKS has its own core technology!

1. Adjustable parameters: Parameters can be adjusted according to the actual needs of customers to achieve the best printing effect. 2. Joint R&D: Jointly develop the application of various new materials with customers and customize the best product full set solutions. 3. Printing

3D打印技术在儿科学中的具体应用

术前模拟: 有助于外科医生在小月龄婴儿心脏腔内实现精准空间定位,并以高保真度模拟手术入路和手术步骤,不仅可以缩短术中时间,还可以降低并发症发生率、失血量、术后住

珠宝领域中基于3D打印技术的可持续设计和制造

首先,可以减少废弃物的产生。 传统的珠宝制作工艺通常需要手动加工和切割等方式进行制作,从而产生一定数量的废料和碎屑。而3D打印技术可以直接生产出完整的产品,减少

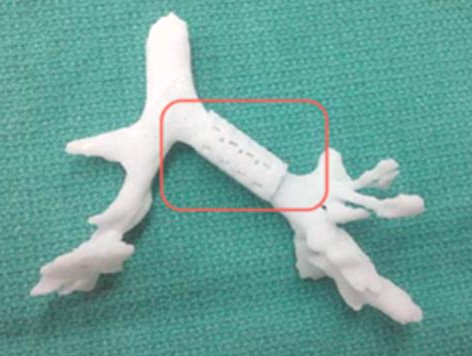

3D打印定制气道支架相关知识

目前,3D打印技术在临床医学、医学模拟教学以及困难气道等方面发挥着重要作用。随着精准医学的发展,临床中对更符合人体工程学和气道疾病特征的气道工具需求不断增加,3

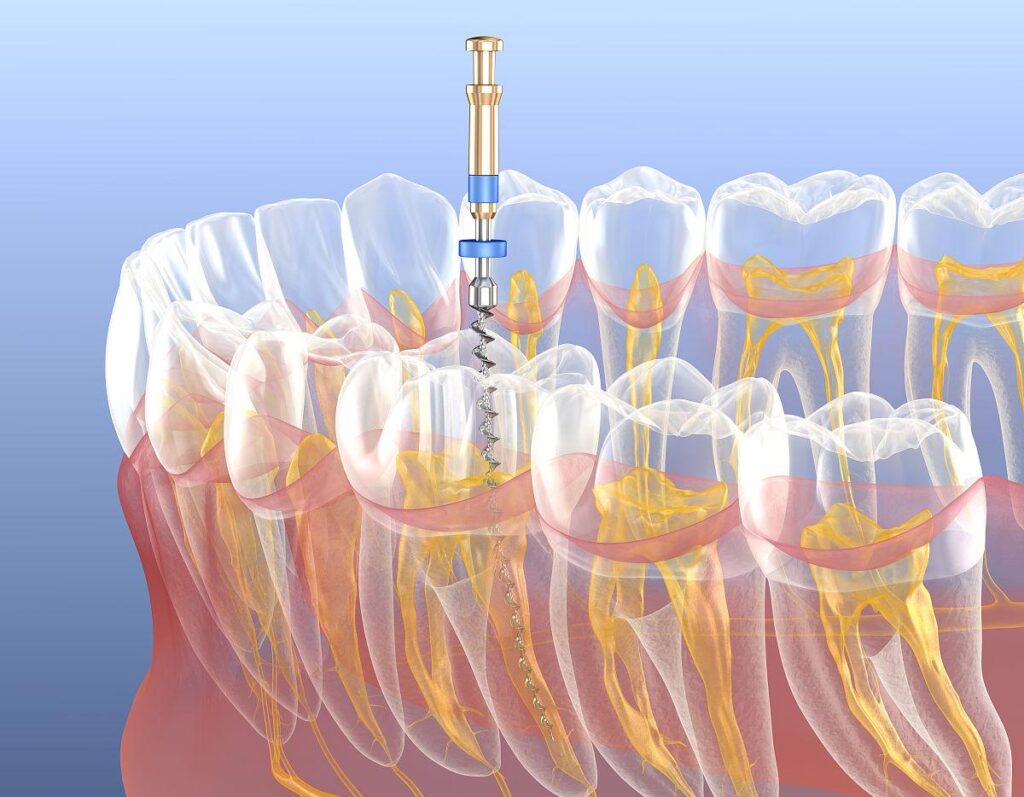

3D打印在微创牙髓治疗中的应用流程

数据采集: 三维重建的第一步是通过计算机断层扫描或者核磁共振,扫描病变区域获得理想的三维数据,并以DICOM格式保存下来。其中CBCT以其扫描时间短、图像分辨率

.png)